Key factors in production processes in the children’s sector: Quality, efficiency, and regulation

Are companies in the children’s sector prepared to respond to an increasingly demanding, regulated, and competitive market? How can they ensure that every garment, toy, or childcare product meets the highest standards without losing efficiency? Production processes have become a strategic pillar for brands that want to grow sustainably, safely, and in line with current regulations.

The importance of well-defined production processes in the children’s sector

In the children’s products industry, there is no room for improvisation. Quality, safety, and traceability are not added values; they are essential requirements. A professional approach to industrial processes enables companies to reduce risks, optimize resources, and strengthen the trust of distributors, families, and regulatory bodies.

From the selection of raw materials to final packaging, every stage must be documented, controlled, and aligned with national and European standards. In this context, having the support of specialized organizations such as ASEPRI is key to resolving doubts, anticipating regulatory changes, and professionalizing production management.

Quality: The pillar that sustains trust

Can a children’s brand grow without a solid quality policy? Hardly. Quality is not limited to the final product; it runs through the entire production cycle: design, sourcing, manufacturing, and control.

Companies in the sector typically work with protocols such as chemical substance controls, resistance testing, finish verification, or supplier audits. Standardizing these procedures not only improves the final outcome but also minimizes incidents, returns, and medium-term costs.

Through its associative work, ASEPRI advises companies on interpreting technical requirements, certifications, and best practices, acting as a reference point in a complex and constantly evolving regulatory environment.

Production efficiency: Competitiveness without compromising safety

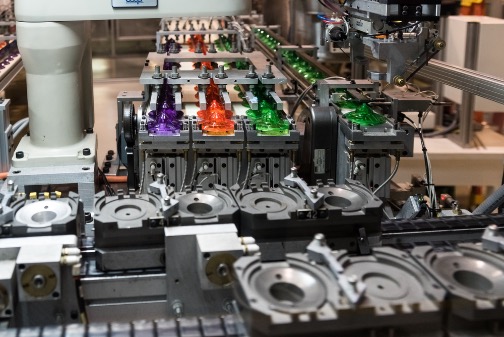

Optimizing resources without compromising safety is one of today’s major challenges. Efficiency in manufacturing systems involves planning, time control, digitalization, and continuous improvement. Today, many companies in the children’s sector are incorporating:

- Production management tools (ERP).

- Automation of repetitive tasks.

- Data analysis to identify bottlenecks.

- Continuous improvement methodologies adapted to regulated environments.

Efficient production processes make it possible to respond better to demand peaks, reduce waste, and improve profitability—particularly relevant in a globalized market. In this area, ASEPRI supports companies by providing sector insight, success stories, and strategic guidance tailored to the reality of the Spanish market.

Regulation and legal compliance: A framework that cannot be ignored

Is your company up to date with all the legal obligations affecting children’s products? Regulation in this sector is particularly strict and covers everything from product safety to labeling, sustainability, and social responsibility.

European regulations, UNE standards, and directives on the safety of toys, textiles, or childcare products require constant monitoring. A mistake in this area can lead to penalties, product withdrawals, or reputational damage.

Here, ASEPRI’s value is distinctive: the association acts as an intermediary with official bodies, translates regulations into business language, and helps companies comply in a practical and efficient way.

Sustainability and traceability: Increasingly decisive factors

Sustainability is no longer a trend but a market requirement. Consumers and distributors demand transparency regarding the origin of materials, manufacturing conditions, and environmental impact. Integrating sustainability criteria into production systems involves:

- Responsible supplier selection.

- Control over the origin of raw materials.

- Energy optimization and waste reduction.

- Clear, verifiable documentation.

These aspects strengthen brand reputation and open the door to new markets. ASEPRI promotes a responsible vision of the sector, offering guidance on sustainability, circular economy principles, and compliance with international standards.

Training and ongoing advice: A strategic investment

Human teams are the driving force behind any production system. Training in regulations, quality, and process improvement is essential to remain competitive.

ASEPRI plays a key role as a knowledge hub, facilitating training, sector reports, and exchange spaces between companies. This support enables organizations to make informed decisions, reduce uncertainty, and anticipate market changes.

FAQs on production processes in the children’s sector

Why are production processes so critical in this sector?

Because they directly affect the safety, quality, and legal compliance of products intended for a particularly sensitive audience: children.

What are the most common mistakes companies make?

Lack of documentation, regulatory unawareness, insufficient supplier control, or the absence of quality and efficiency indicators.

How can ASEPRI help my company?

By offering expert advice, up-to-date information, specialized training, and institutional representation before regulatory bodies.

Is efficiency incompatible with safety?

No. Proper planning and standardization make it possible to improve efficiency while maintaining—and even strengthening—safety and quality levels.

Is it mandatory to integrate sustainability criteria?

Increasingly, regulations and clients require it. Anticipating this represents a clear competitive advantage.

Investing in solid, efficient, and regulation-aligned production processes is not only a legal obligation but a strategic decision. Relying on sector expertise and the support of ASEPRI enables companies in the children’s sector to move forward with confidence, credibility, and a long-term vision. Contact us and we’ll help you!